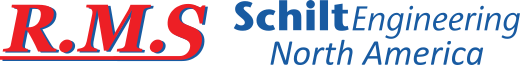

RMS SPIRAL BENDER

The RMS Spiral Bender will take straight or coiled rebar and fabricate consistent diameter spiral and hoop shapes efficiently and accurately with adjustable pitch.

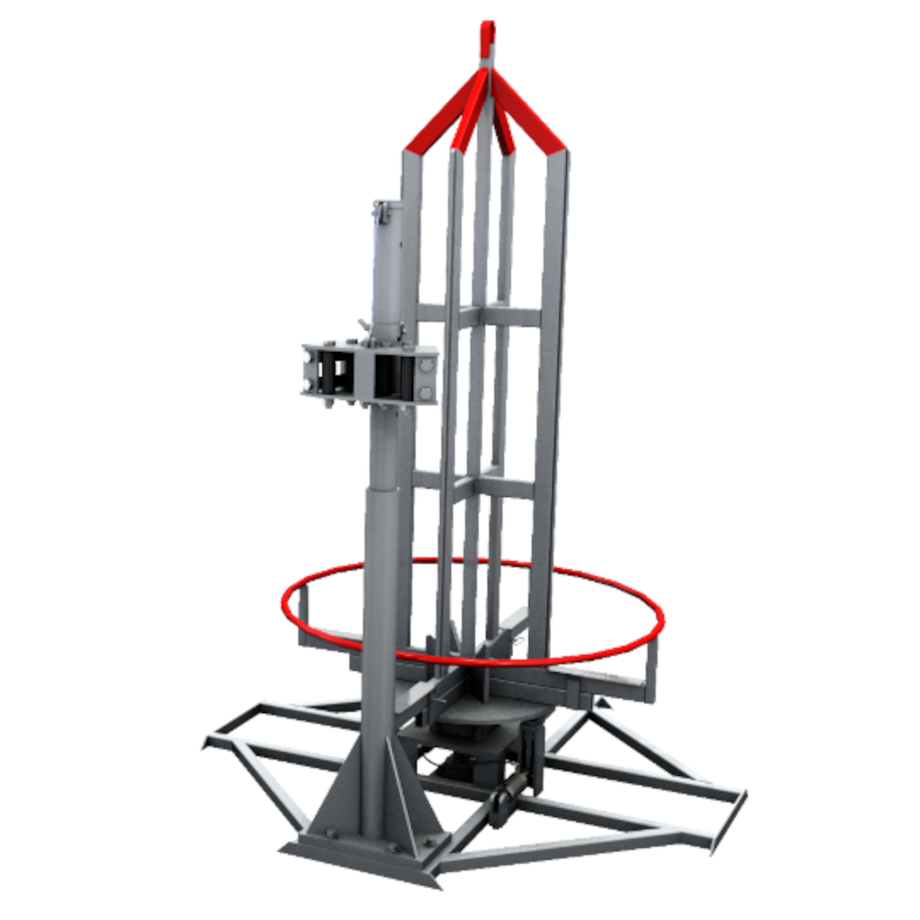

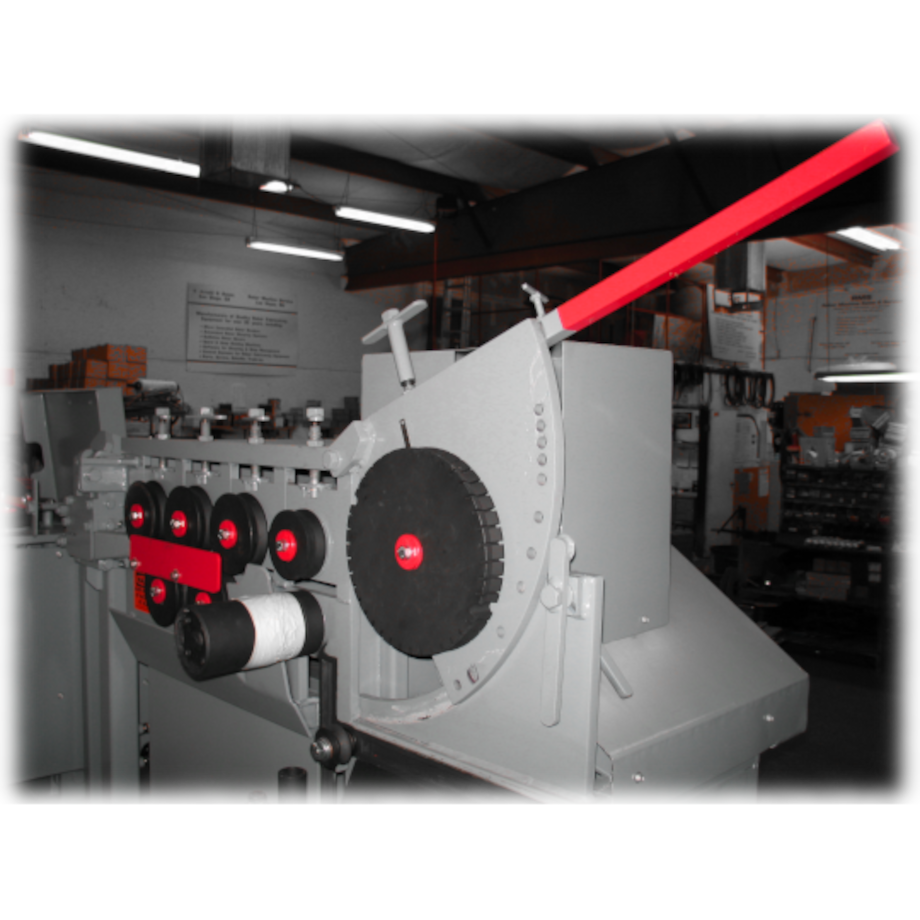

The spiral machine’s drive system is comprised of two independent variable speed motors and powered drive rolls. This assures efficient and accurate forming of the shapes being fabricated.

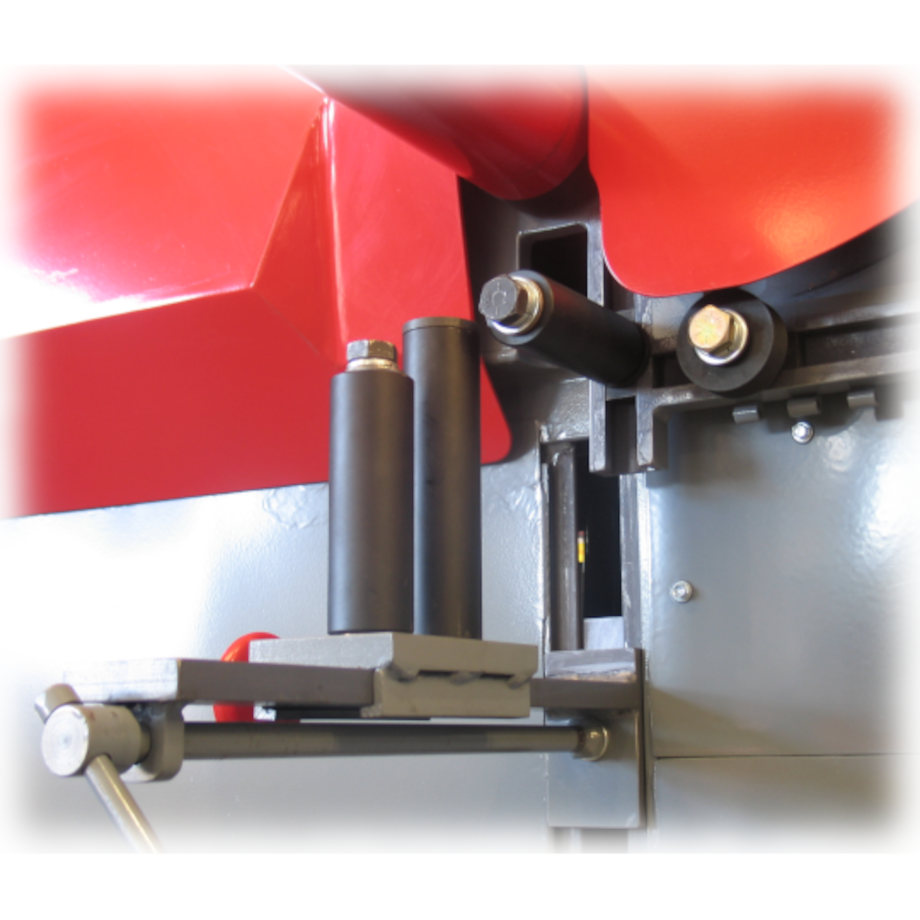

Operator programmable motor controller includes the jog mode, variable speeds (forward and reverse), soft start and stop, and many more parameters.

This micro controlled system enables the operator to preset any number of turns, identical hoops or spirals, and diameters. It will store bar size and diameter for future recall and quicker future setup.

The spiral machine is constructed from structural steel members/plates and designed with low maintenance requirements to assure a long and dependable service life.

MACHINE SPECIFICATIONS

5HP ROLLER MOTORS W/ GEAR REDUCTION [3.7kW]