Rebar Machine Service

The strongest name in rebar fabrication

RMS was founded over two decades ago by many of the same key people responsible for introducing the first automated table top bender to the industry as far back as the early 1960s, known as the Arnold Bender. Today, RMS technology incorporates the same rugged and robust qualities as the original Arnold equipment, together with cutting-edge micro technology, resulting in products that are long lasting, safe, and unmatched in terms of productivity.

RMS offers a complete line of Micro-Controlled Rebar Benders, including the #11, #14, #18, and the Stirrupmaster which is a specialty machine for bending ties and stirrups.

The RMS Model 611 Hydraulic Guillotine Shear was pioneered by RMS over 30 years ago continues to be the choice of rebar fabrication facilities around the world. In addition to the 611 Shear, we also offer an intermediate shear, the 411 Shear, and the Mini Shear, which is designed especially for smaller rebar shops, precasters, and masonry companies.

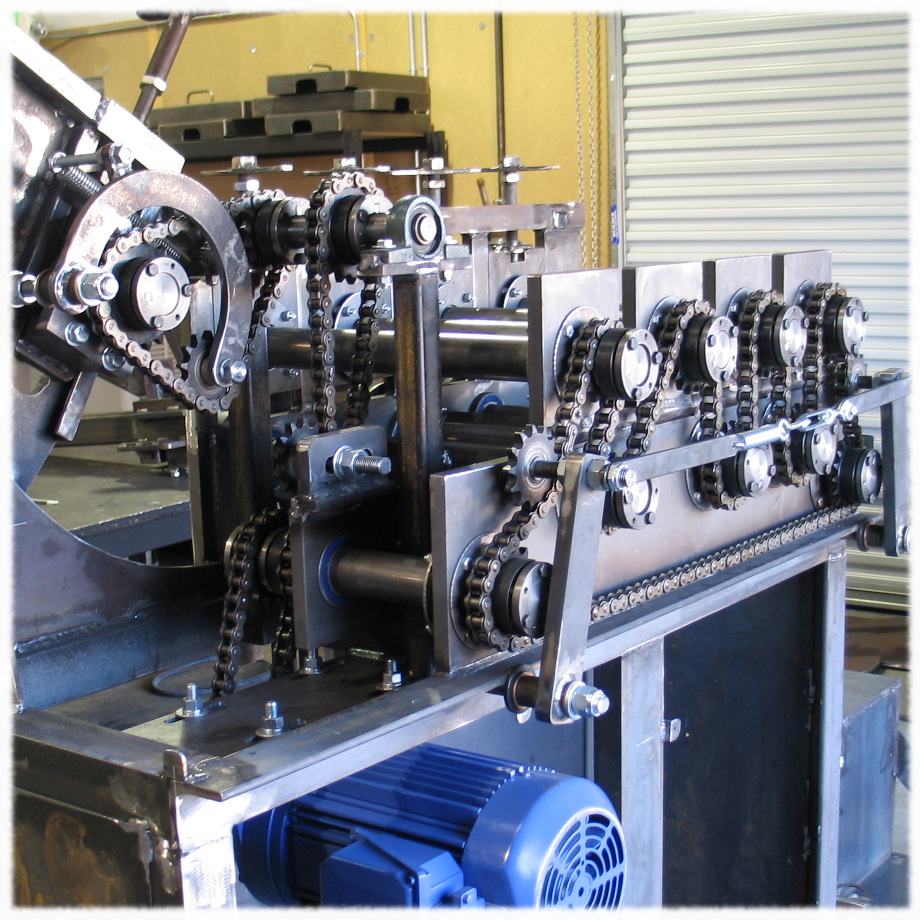

The RMS Shearline, coupled with the RMS Hydraulic Shear, represents a truly efficient, safe, and productive method of shearing rebar. RMS Shearlines can be found at work in shops throughout the world, some producing day in and day out after more than 20 years of service. The RMS Shearline was designed using the heaviest components, state of the art electronic and pneumatic technology, and a rugged structural steel design. Cutting data can be entered directly into the shearline micro controller, or by using rebar production software to load the controller via USB or RS-485.

Among the other products offered by RMS are a Micro-Controlled Spiral Machine and a Micro-Controlled Radius Machine; both of which receive much acclaim in the rebar fabrication industry.

The RMS sales department is headed by Fred Kerr, with more than 35 years of rebar fabrication experience and by Brett Kerr, V.P. of sales, with over 10 years of hands-on experience.

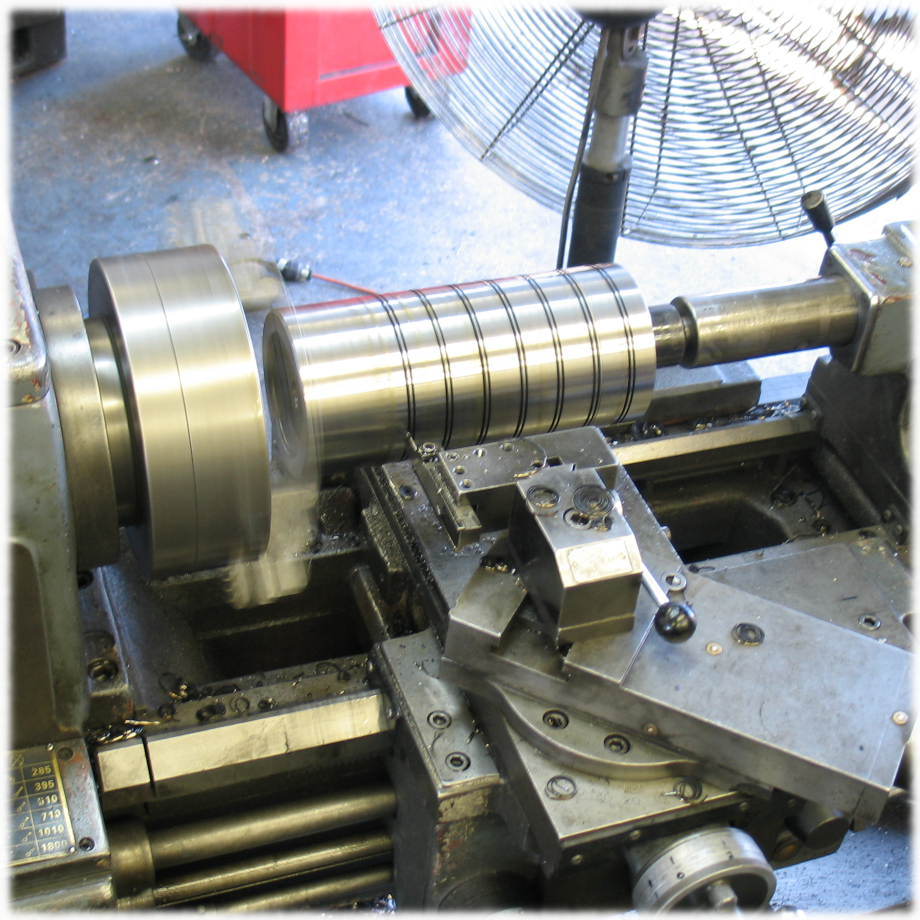

The manufacturing facility, located in Las Vegas, NV, is led by Dave Green as its president. Many of the RMS employees have been with the company since its inception over 30 years ago. This invaluable experience assures that each machine built and shipped by RMS is of the highest quality and workmanship.

The RMS research and development department has maintained a top-notch level of expertise in the design and development of control systems for all equipment, utilizing the most up-to-date technology. The RMS control systems are considered the most advanced, yet user friendly systems available in the industry.

Please feel free to contact RMS directly for more information. We look forward to the opportunity of providing service to you.