RMS Shearline

The RMS Shearline is a result of many years of experience in both rebar fabrication techniques and equipment manufacturing. RMS has built its reputation on providing the best equipment available, at competitive prices, plus unmatched service and support to customers around the world.

RMS Shearlines can be found at work in many of the leading rebar fabricating shops, ranging from those whose volume is minimal to some of the largest producers in the world. It is not uncommon to find RMS Shearlines built 10, 20, or even 30 years ago, still at work.... still producing day in and day out.

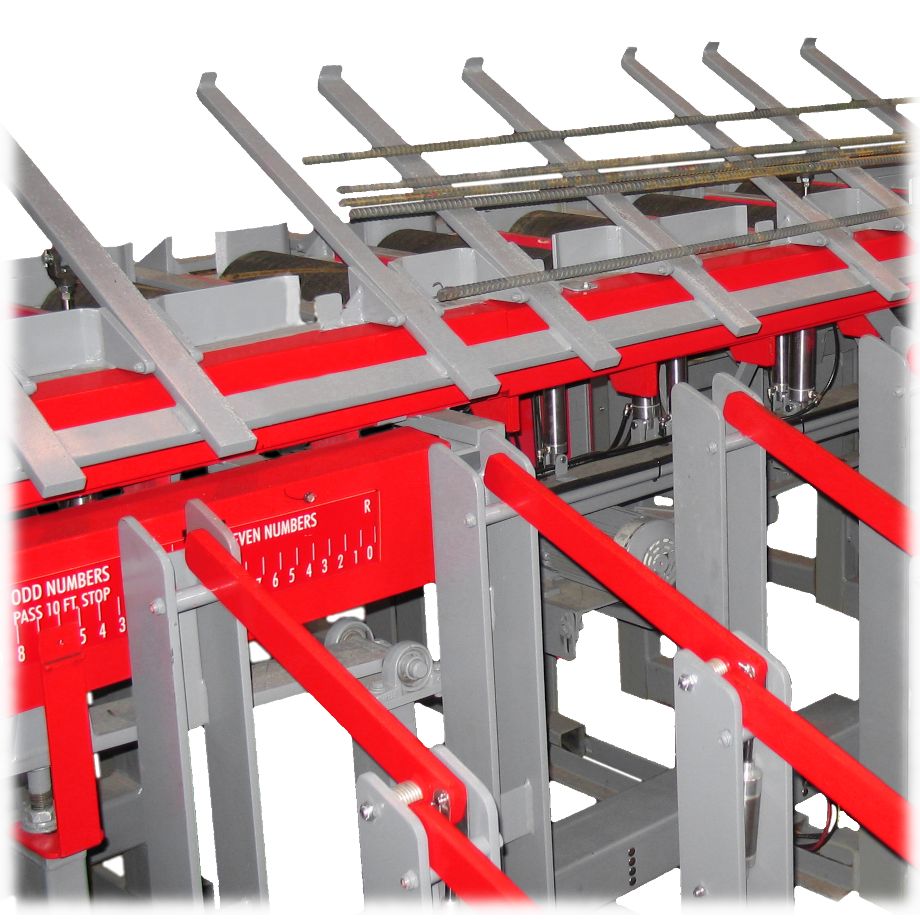

Every RMS Shearline is built to the most uncompromising standards, including heavy-duty components, a box channel frame, the heaviest kickoff and bin arms and long-lasting conveyor rolls. Low maintenance and highly efficient performance are just some of the traits that make the RMS system the choice of rebar fabricators of all sizes.

heavy-duty parts and components are a trademark of RMS shearlines, including large diameter conveyor rolls, heavy steel kickoff arms spaced at 24-inch centers, high capacity kickoff cylinders and heavy bin arms

Bins are spaced at specific intervals to maximize the storage of various lengths of bundles. A higher pass-line provides greater bin space, plus a steeper kickoff slope, assuring that bars and bundles slide efficiently into the selected bin pocket.

A unique short bar shearing section reduces much of the “manual handling” of short bars. A mobile short bar bin system collects short bars and easily moves away from the gauge table for tagging and removal of the sheared material. Bin arms are air activated and easily disconnected when bin section is moved.

The preload table is designed to allow the preparation of up to two loads of steel ahead of the operator, even while the conveyor is in use. Extra storage tiers are available on one or both sides of the conveyor. Independent preload controls permit the “shakeout” man to operate the entire table from his shakeout platform.

RMS Shearlines can be used efficiently with virtually any shear. Modular design allows simple addition of many components, such as foot stops, bin assemblies or conveyor sections.

Machine can easily be equipped with the RMS Bar-Prep system to reduce shakeout time. Bin interior, conveyor roll and kickoff arm protection available for shearing epoxy bar.

MACHINE SPECIFICATIONS

[708 to 991LPM @ 6.9bar]