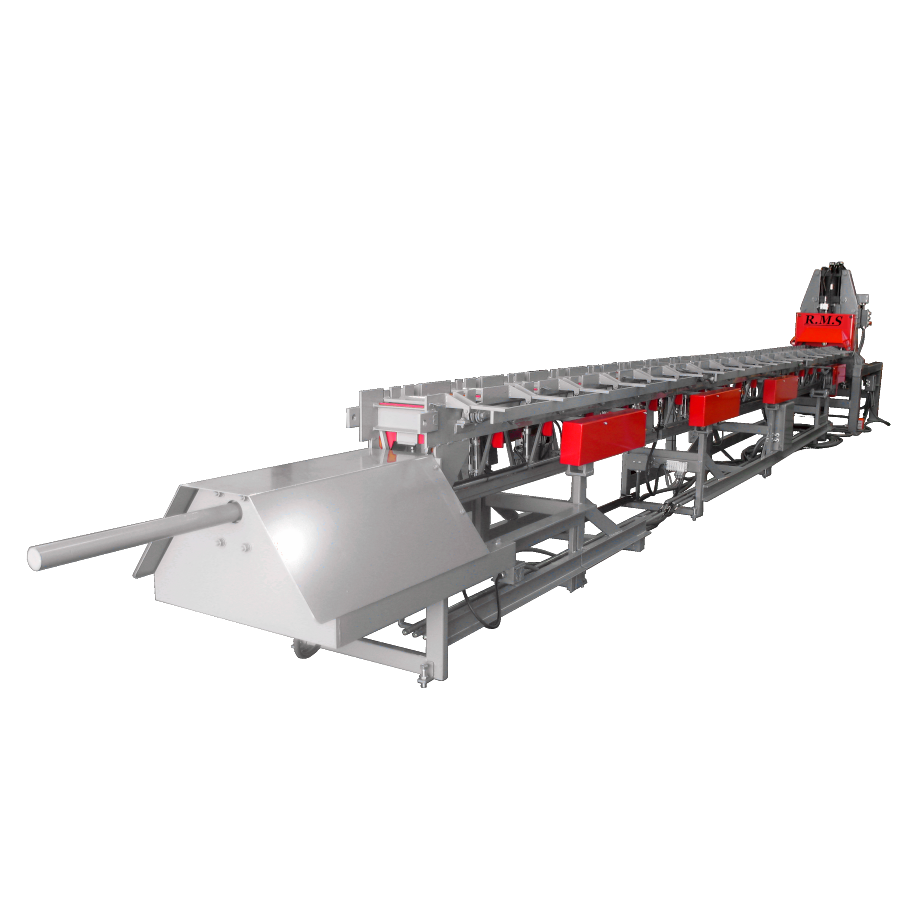

RMS Mini Shearline

The RMS Mini Shearline is a heavy duty, yet economical rebar shearing system designed for smaller rebar fabricators, secondary shearlines, and the precast industry. RMS has built its reputation on providing our customers quality parts, industry-leading customer service, and competitive pricing.

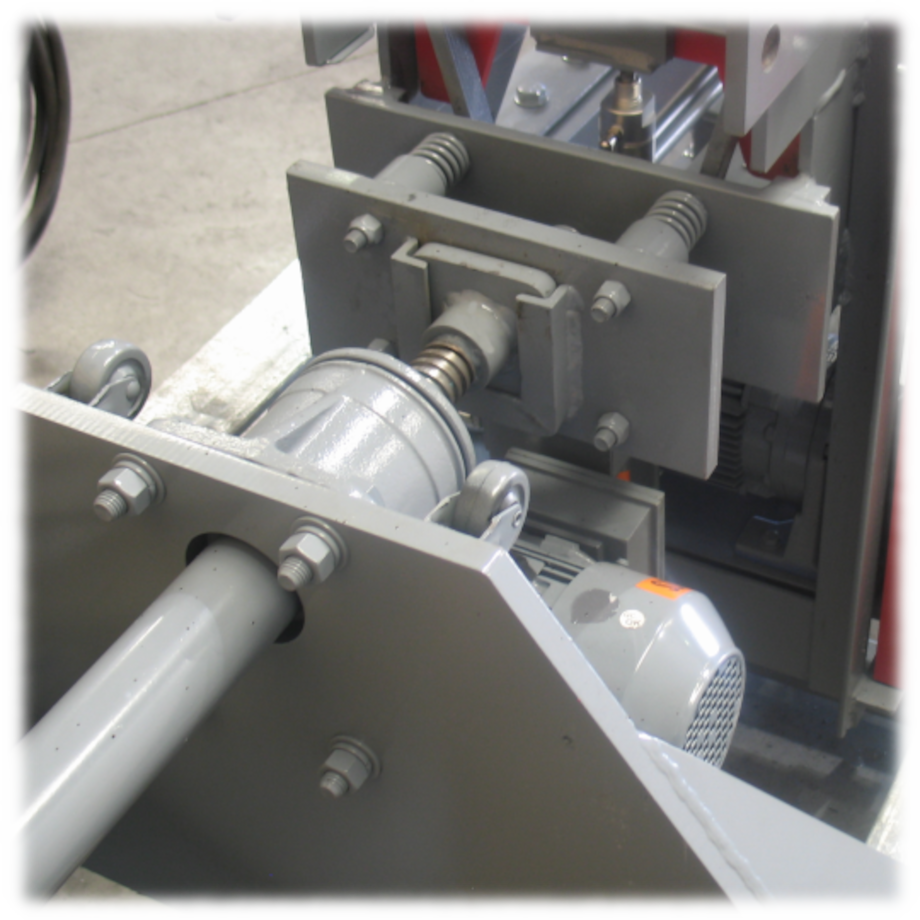

RMS shearlines, including the mini shearline, are fabricated using structural steel to ensure that the machine will hold up to decades of rebar processing. After the machine is framed it receives only high-quality bearings, belts, and pneumatics to ensure there are only minimal maintenance requirements.

The Mini Shearline can be used efficiently with the RMS Mini Shear or the RMS 411 Shear. Modular design allows simple addition of many components, such as foot stops, bin assemblies or conveyor sections.

The stock table can easily be equipped with the RMS Bar-Prep system to reduce shakeout time. An air kickoff is provided on both sides of the conveyor, allowing bin pockets to be placed on either side.

The RMS Mini Shearline has been designed from the ground-up to be easily installed by the customer without assistance. Detailed installation instructions and electrical schematics are provided with the machine.

MACHINE SPECIFICATIONS

[283 to 566LPM @ 6.9bar]